+86-15821815423

sales@jadetransparts.com

.I Introduction

1. Application

• Mechanical or low-speed motorized spindles of CNC machine tools.

• Hydraulic stations or lubrication stations of CNC machine tools, oil presses

and machinery.

• Working fluid cooling for electrical discharge machines.

• Lubricating/cooling system of reduction boxes, like Germany ZF reduction gearbox, Italy BF reduction gearbox and self-made gearbox.

MCO / Inverter Oil Chiler

Tongfei brand

.I Introduction

1. Application

• Mechanical or low-speed motorized spindles of CNC machine tools.

• Hydraulic stations or lubrication stations of CNC machine tools, oil presses

and machinery.

• Working fluid cooling for electrical discharge machines.

• Lubricating/cooling system of reduction boxes, like Germany ZF reduction gearbox, Italy BF reduction gearbox and self-made gearbox.

2. Functions and Features

• The control system adopts a control ler with Chinese / English ( switchable ) LCD, making ti visual and easy-to-operate.

• Two control modes, including fixed temperature and difference-controlled temperature, are available for your choice.

• tI serves multiple functions with passive alarm terminals, sending fault signals to CNC system.

• Remote start terminals are available for gang control between machine tool and oil chiller.

•

R$485 communication interface can be added to implement communication function.

•

To prevent the spindle of CNC machine tool from affecting the machining accuracy due to changes in oil temperature

• To prevent spindle from off-centering or thermal deformation, stabilize the precision and prolong the service life of machine tool.

• To prevent oil deterioration caused by high oil temperature, maintain oil viscosity and avoid oil shock.

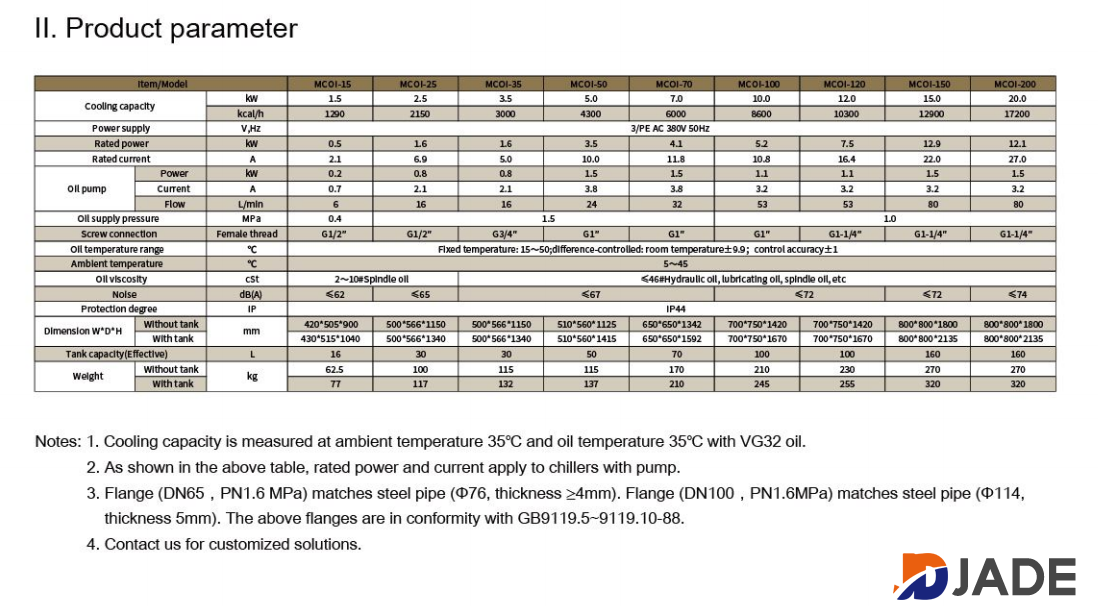

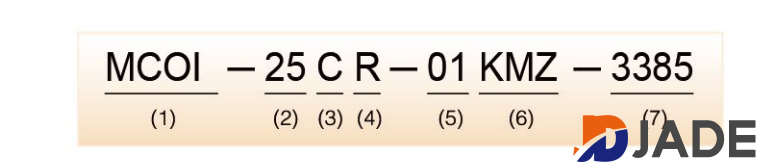

3. Model Description

MCOI - 25 C R - 01 KMZ - 3385

(1) Product series:

MCOl: Inverter oil chiller

(2) Cooling capacity: (×100W)

25: Cooling capacity =25x100W=2500W (3) Structure:

A: Without pump or tank (For hydraulic pump station cooling, the hydraulic station needs a pump to continuously supply oil to the chiller)

B: With a pump but without tank (For hydraulic pump station or open system cooling)

C: With a pump and tank (For closed system or spindle cooling)

D: With a tank and two pumps (For open reduction gearbox or gearbox

cooling)

(4) Additional functions:

R: With heating function (Without heating function, there is no "R".)

(5) Design serial number: there is a need for modification in case of great

structural changes

01: General series number

(6) Special requirements: Be omitted for no special requirements

K: Special requirements for interface

M: Al labels and packing technical documents are written ni English

Z: High temperature environmentally friendly refrigerant (7) Power supply:

The first digit: phase

The second/third digits: the first two figures of voltage

The forth digit: frequency 3385: 3/PE AC 380V 50Hz

4. Precautions for use

[Danger] The connected power system is consistent with the product nameplate;

[Warning] The pressure of tubing and joints must be greater than the oil supply pressure of the oil pump;

[Note] The selected tubing diameter should be consistent with the interface diameter of the oil chiler, and the length should not exceed

the pressure loss parameter value of the oil chiller;

[Note] No solid objects larger than 50um are allowed in the oil; No wire or filamentary material with diameter or thickness greater

than 1mm and length greater than 3mm is allowed; Corrosive media such as sulfur are not allowed;

[Note] When designing and connecting pipelines, reduce the pressure loss of pipelines as much as possible. Such as: reduce the right Angle joint, reduce the valve, appropriately increase the curvature radius of the pipeline and the pipeline diameter (related ot the oli supply pressure and folw rate), efectively ensure the smooth folw of hte pipeline, reduce the pressure loss.

[Note] Make sure that the oil pipeline and electrical connection with the machine tool host are correct.

[Note] Make sure there is enough oil in the oil system and that the pipelines are not blocked.

Contact: Caroline Wang

Phone: +86-15802132080

E-mail: sales@jadetransparts.com

Add: C-42, No. 386 Yangtai Road, Baoshan District, Shanghai,China