+86-15821815423

sales@jadetransparts.com

I. Introduction

1 . Application

• CNC gear hobbing, broaching, shaping, grinding and honing machines.

• CNC honing machine; internal, cylindrical, crankshaft and screw grinders;

deep-hole processing drilling machines.

• CNC machining center.

• CNC lathe, milling and broaching machines.

• EDM machines, electroworking fluid and hydraulic pump stations.

MCS / Immersion chiler

I. Introduction

1 . Application

• CNC gear hobbing, broaching, shaping, grinding and honing machines.

• CNC honing machine; internal, cylindrical, crankshaft and screw grinders;

deep-hole processing drilling machines.

• CNC machining center.

• CNC lathe, milling and broaching machines.

• EDM machines, electroworking fluid and hydraulic pump stations.

2 .FunctionsandFeatures

•As for the control system, a controller with Chinese / English LCD si employed, making it easy-to-operate. The controller featuring automatic fault diagnosis can display fault points on the screen, hence reminding

the user of rapid processing.

Two control modes, including fixed temperature and difference-controlled

temperature, are available for your choice.

tI serves multiple functions with passive alarm terminals. Fault signals are sent back to CNC system, providing protection for machining.

• Remote start terminals are provided to realize gang control between machine tool and immersion chiller.

• RS485 communication interface can be added to implement communication function.

• Directly installing on liquid tanks can avoid the impact from impurities, oil sludge, metal filings, contributing to the maintenance work.

• Featuring corrosion resistant, easy-to-clean, high-efficient and energy-saving, evaporating coils without a welding joint are made from stainless steel or copper with coating surface, which are suitable for various fluids.

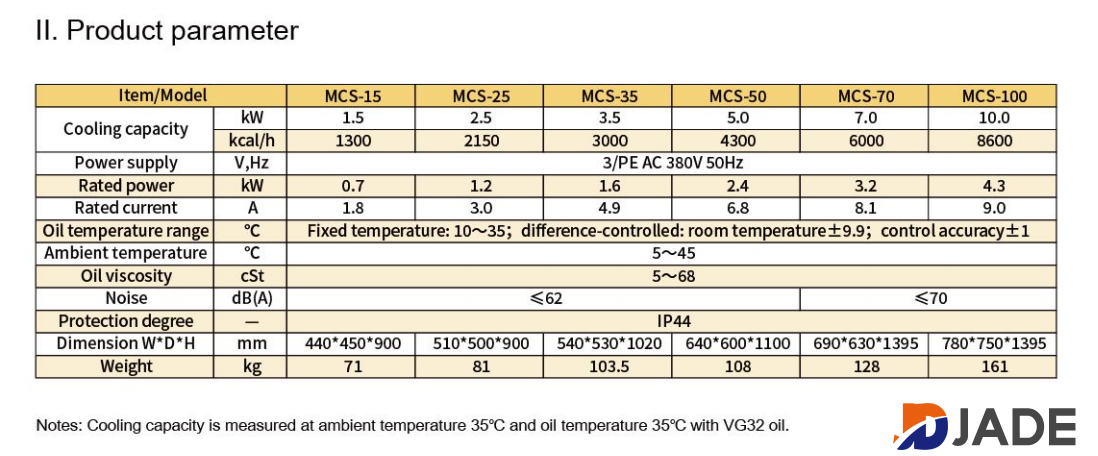

3.ModelDescription

MCS - 25 S R - 01 MOPZ - 3385

(1) Product series:

MCS: Immersion chiller

(2) Cooling capacity: (×100W)

25: Cooling capacity = 25× 100W=2500W

(3) Structure:

S: Immersed coil tube

(4) Additional functions:

R: With heating function (Without heating function, there is no "R".)

(5) Design serial number: there is a need for modification in case of great structural changes

01: General serial number

(6) Special requirements: Be omitted for no special requirements M: Al labels and attached documents are written in English 0: Coil tube is made from stainless steel

P: Special requirements for immersed depth of coil tube

Z: Eco-friendly refrigerant

(7) Power supply:

The first digit: phase

The second/third digits: the first two figures of voltage The forth digit: frequency

3385: 3/PE AC 380V 50Hz

Contact: Caroline Wang

Phone: +86-15802132080

E-mail: sales@jadetransparts.com

Add: C-42, No. 386 Yangtai Road, Baoshan District, Shanghai,China